Union Polymer Core Technology

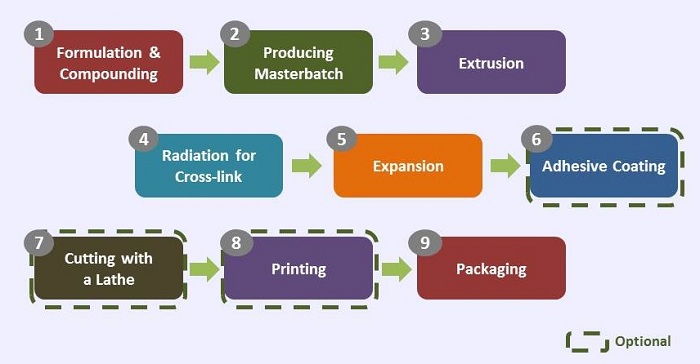

In general, our heat shrink tubing manufacturing process includes the following nine steps:

Formulation & Compounding Technology - Our on-site R&D and compounding center has developed varieties of formulations for different heat shrinkable applications. Our engineers have worked closely with OEM customers developing cutomized products to meet their specifications.

Extrusion - The extruder acts as a pump to supply a continuous stream of thermoplastic compound to shape the material into a tubing product. In addition to the regular extrusion technology, our co-extrusion technology enables us to manufacture semi-conductive/insulation double layer tubing, semi-conductive/elastomeric insulation double layer tubing, and semi-conductive/insulation/elastomeric insulation tri-layer tubing.

Cross-link - The unique heat shrinkable product properties are obtained through cross-linking process. Our on-site electron beam (E-beam) accelerator for radiation cross-linking ensures quality control, shortens lead time, and facilitates new/customized product development.

Expansion - Expansion is a key step to obtain the final forms of heat shrinkable products. We have multiple continuous expansion equipments to accurately control the dimensions, longitudinal shrink ratio, and concentricity of the final products.

Cutting - We provide value added cutting services to our customers. Our cutting equipments for medium and heavy wall tubing were specifically designed by our engineers.

Printing - We provide cutomized printing to our customers.

Packaging - We provide private label services to our customers

|

|

Inquiry or Order: (513) 899-1618 | Email: Info@Union-Polymer.com

Union Polymer International Copyright © 2016. All Rights Reserved